Rheonik Messgeräte GmbH has more than twenty years of experience in the field of Coriolis Mass Flow meter design and development. Beginning in 1984, Karl Küppers began the design of a mass flow meter based upon the Coriolis effect that later became the patented Omega tube Coriolis Mass Flow meter manufactured by Rheonik today.

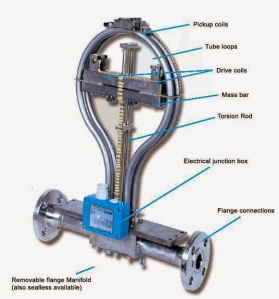

After the exhaustive testing of many different designs, the Omega tube meter with torsion rods and mass bars was granted a patent based upon its unique operation and construction feature. Compared to other meter designs, the Rheonik Omega tube design offers outstanding performance and mechanical reliability.

All Rheonik coriolis mass flow meters are based on a patented Omega tube design with increased signal-to-noise ratio, for excellent performance and reliability. The combination of a patented torsion rod swinger with the Omega shape and support bars results in high accuracy measurement independent of pressure, even at very low flow velocities.

RHM Coriolis Sensors Overview from Rheonik Messtechnik GmbH : |

|

Model

|

Qmin

|

Qmax

|

Qnom

|

pmax @ 120°C

|

typical size of process connection

|

|

|---|---|---|---|---|---|---|

|

kg/min

|

kg/min

|

kg/min

|

bar(g)

|

thread

|

flange

|

|

|

0.002

|

0.6

|

0.6

|

700

|

1/4″

|

DN15, 1/2″

|

|

|

0.038

|

5.0

|

5.0

|

870

|

1/4″

|

DN15, 1/2″

|

|

|

0.05

|

10

|

10

|

870

|

1/4″

|

DN15, 1/2″

|

|

|

0.15

|

20

|

20

|

510

|

1/2″

|

DN25, 1″

|

|

|

0.30

|

50

|

50

|

1,185

|

1/2″

|

DN25, 1″

|

|

|

0.75

|

100

|

75

|

960

|

3/4″

|

DN25, 1″

|

|

|

1.00

|

200

|

150

|

815

|

3/4″

|

DN40, 1 1/2″

|

|

|

2.25

|

300

|

300

|

700

|

1″

|

DN50, 2″

|

|

|

5.0

|

750

|

600

|

700

|

—

|

DN80, 3″

|

|

|

12.5

|

1,500

|

1,250

|

290

|

—

|

DN80, 3″

|

|

|

45

|

3,000

|

2,500

|

430

|

—

|

DN100, 4″

|

|

|

130

|

8,000

|

5,000

|

215

|

—

|

DN150, 6″

|

|

|

200

|

12,000

|

10,000

|

150

|

—

|

DN200, 8″

|

|

|

600

|

30,000

|

23,000

|

50

|

—

|

DN300, 12″

|

|

- Measurement of liquid and gaseous fluids

- Flow rates from 0.002 to 30,000 kg/min (0.004 to 66,000 lbs/min)

- Diameters up to 12 inch / DN 300

- Pressure over 1,000 bar (14,500 psi)

- Temperature from -196°C to +395°C (-320°F to +743°F)

- Hazardous area certified versions available (ATEX, CSA etc.)

- Available in stainless steel, Alloy C22, Duplex, Tantalum and others

- No change of accuracy with changing pressures – active measurement section is half round and maintains its exact shape at any pressure

- Active measurement section of the Omega is de-coupled from process connections via mass bars. Vibrations have less influence on measurement than with conventional Coriolis meters

- Tensions from the process side cannot disturb active measurement section of Omega since it is de-coupled (straight tube shaped meters are very vulnerable in this regard)

- Mass bar and torsion rods (rods work as a spring) form a harmonically oscillating system, resulting in great stability and little energy needed (therefore intrinsically safe)

- Mass bar – torsion rod system provides very big amplitudes, hence excellent signal to noise ratio. Even smallest rates can be measured reliably.

- Straight tubes have low signal to noise ratio

- Torsion oscillator allows bigger wall thickness, hence higher pressure ratings, increased safety, and extreme temperature possible

- Torsion movement instead of bending creates less stress in tubes – longer life time

- Torsion movement is less affected by pipe vibrations since the vibrations are horizontal or vertical. Operational movement (torsion) is not in the same plane as the vibration movements – less cross talk

- Compact form. Shorter face-to-face length than straight tube shaped meters

- Separate transmitter for flexibility – easy to integrate into systems

- Extreme applications

- Sensor models rated over 1,000 bar are available

- Temperatures from -196°C to +395°C

- Highest accuracy under real-life conditions

- Units available for fiscal duties

- Low energy usage

- EEx ia IIC sensors available (ATEX and CSA)

- Flexible configuration

- Diameters from ½” to 12″

- Wetted parts materials available: stainless steel, Alloy C22, (Super) Duplex, Tantalum and others

- Suitable for virtually any mass flow application, such as: Batching, Dosing, General flow control, Injections, Filling

- Loading of boats, vessels, rail tank wagons

- High temperatures and other challenging applications

- Highly viscous media (low pressure drop and excellent performance at low flow conditions)

- Properly used for corrosive liquids and Low Flow

- Properly used for beverages that require food grade instrument

- The outstanding features include : Suitable for pressure up to 450 bar

- Size : 1/4″ – 12 ” :

- Measuring ranges : 0.002 kg/min to 25.000 kg/min ( depending on pipe size )

- Accuracy : 0.1% and better

- Repeatability : better than 0.05%

- Optimised solutions for your batching operation

- Extra compact design with minimal space requirement

- EEx Approvals (i.e. ATEX, CSA, …)

- Custody Transfer Approvals (i.e. PTB, NMI, …)

- As heavy duty version available (increased wall thickness of measuring pipes for additional safety – 250 bar)

- Typical measuring ranges : 0.002 kg/min to 25.000 kg/min

- Flow Accuracy : 0.1% and better

- Repeatability : better ± 0.05% of rate

- Density : better than ± 0.001 g/cc

- Temperature : -200 to +350°C

- Pressure range : Measuring Loops max. 93 bar – max CL 600 / PN 40

- Material of Wetted Parts :

- 1.4571 / SS 316Ti (standard),

- 1.4539 / SS 904L on request,

- Hastelloy C22 on request

- Tantalum and Other material on request

- Housing :

- Stainless Steel: 1.4301 / SS 304 ( standart) and others on request

- Protection class: IP 65 (Nema 4X) and higher on request

- Electrical connection

- Junction box / aluminium coated (standard) IP 65 (Nema 4X) (Junction box in SS optional)

- Cable entry M25 x 1.5 (M20 x 1.5, ½” and ¾” NPT optional)

- Max cable length between RHM and RHE :

- 100 m (330 ft)

- 200 m (660 ft) only with factory approval

- Approvals

- ATEX (CESI 02 ATEX 053 X) : Ex II 1 G, EEx ia IIC T6-T1

- CSA (220705) Class I, Div 1 and 2, Groups A, B, C and D;Type 3

- Custody Transfer Approvals (PTB 1.32-97027224 and NMI TC 3382)

- PED according to directive 97/23/EC available

- 3A Sanitary Approvals

- Transmitter and Display mounting : wall mounting, Pannel Mounting, Rack Mounting

- Outputs :

- 2 analog outputs,

- 1 frequency/pulse output

- 3 digital outputs (Lt, +/-, error…)

- Inputs : 2 inputs (hold, reset, zero)

- Power supply :

- 230 VAC +/- 10% or

- 115 VAC +/- 10% or

- 24 VDC

- Cable entries: 4 x M25 x 1.5 – others optional

- Interface :

- RS 422/485/232 – optional

- HART – optional

- Power consumption : < 15 W